Inductive brazing fixtures

All inductive brazing fixtures are suitable for mounting on our brazing machines.

We are your qualified contact person for the planning, new development and manufaction for simple up to complex inductive brazings for all induction machines.

We look forward to receiving your call under +49 6272 9217-500

Brazing fixtures

The brazing material carried out by means of suitable solder rings, brazing clips, manual brazing wire and flux or with flux-coated brazing wires.

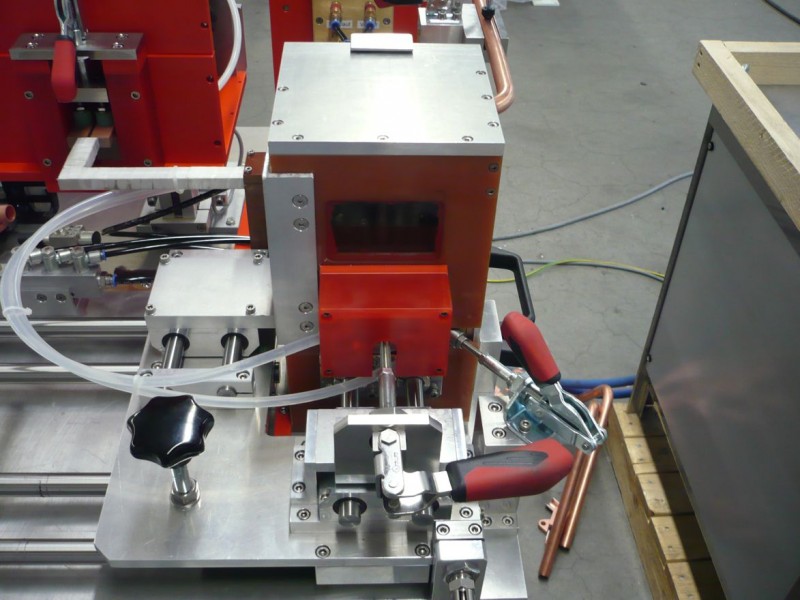

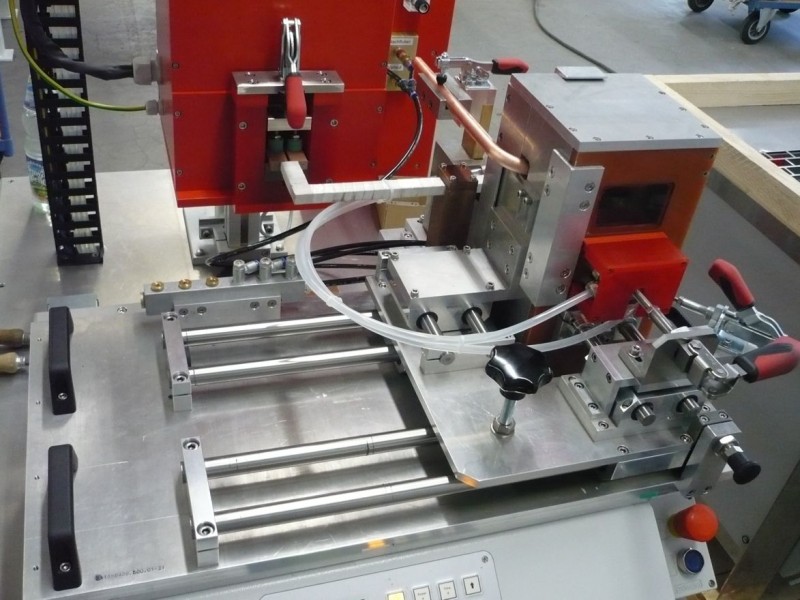

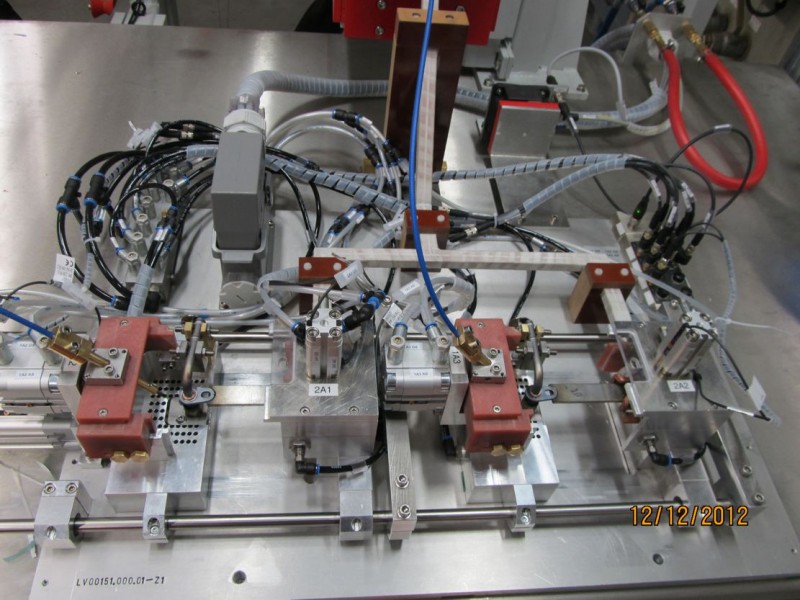

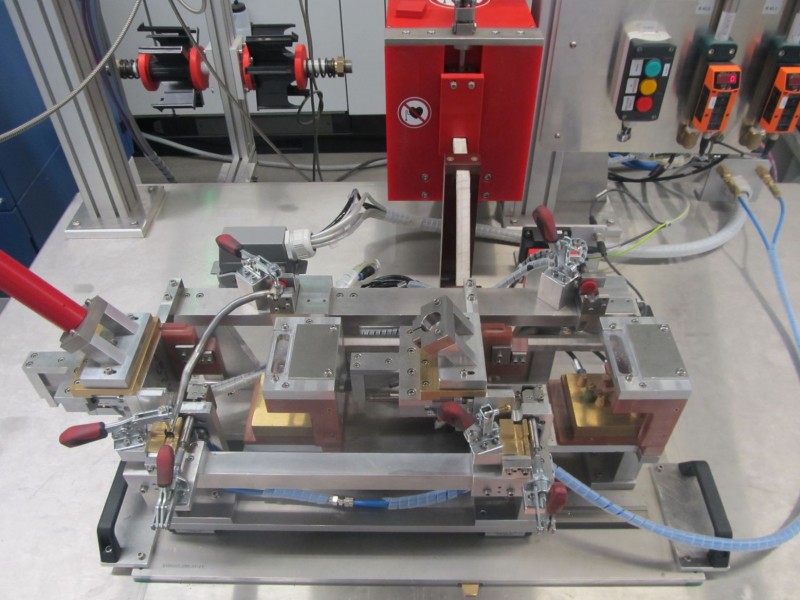

The inductors have connection block for the quick-change system and the inductors are mounted on a base plate and also connected to the quick-change system. On the base plate there are high quality machined part holders. The part will be clamped with manual clamping devices or over pneumatic cylinders. The inductor could be a multiple part brazing device. Depending on the part there can be brazed from 1 up to 5 parts simultaneously.

Inert gas brazing fixtures

The brazing material carried out by means of suitable solder rings, brazing clips, manual brazing wire without flux. The fixture will be flooded with inert gas before, in between and after brazing.

The inductors are mounted on a base plate and also connected to the quick-change system. Around the inductors there is inert gas housing, where inside the clean atmosphere is.

The inert gas fixture is a high quality machined device. The part will be clamped with manual clamping devices or over pneumatic cylinders.

The inert gas fixture could be open and closed manually or pneumaticly. The inductor could be a multiple part brazing device. Depending on the part there can be brazed from 1 up to 5 parts simultaneously.

We will be pleased to consult you on this subject. We look forward to hearing from you!