Inductive Hardening Equipment

Hardening by induction hardening systems usually involves partial heating of the components. The structural transformation ("Austentisieren") is brought about by the induction principle.

Advantages are short heating times, minimal distortion, partial heating, uniform heat input, low scale formation, easy connection in fully automatic production lines.

Surface hardening, Stress-relieving/ tempering/ annealing, Hardening ofDrive shafts, gear racks, shafts, rotationally symmetrical components.

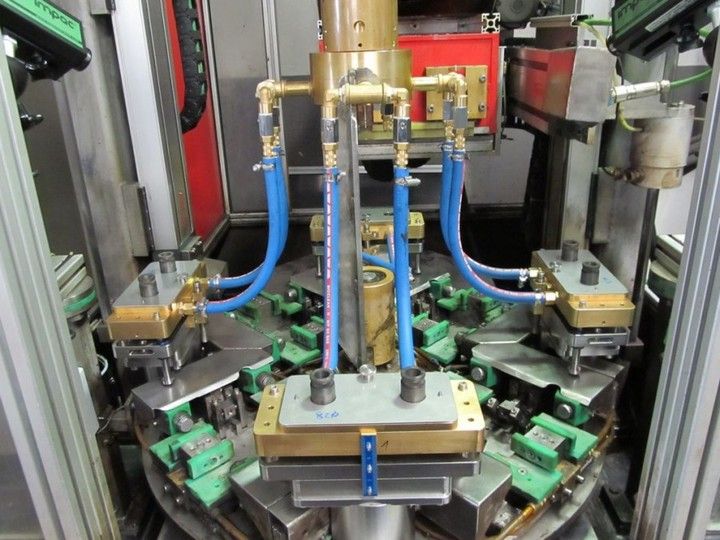

Universal machine for small to medium component lengths, different parts are possible due to device changes.

Hardening / brazing of 3-5 components at the same time (also with inert gas)

Ideal for Inductive heating, soldering and joining for electric motor constructions. The chassis can be made of aluminium or cast iron.